Reduces Cost of Ownership

Ensures Forklift Uptime

Easy on Maintenance

Solid Resilient Tyres, also known as non-pneumatic tyres, are commonly used in heavy-duty applications such as forklifts, industrial vehicles, and construction equipment. These tyres are made from solid rubber, polyurethane, or other materials, and are designed to offer several advantages over traditional pneumatic tyres, including increased durability, resistance to punctures, and reduced maintenance requirements. However, despite their many benefits, solid tyres also require proper care and maintenance to ensure their continued safe use.

Here we suggest some important safety and service points for solid tyres

Solid Tyres should be inspected regularly for signs of damage, wear, or other issues that could affect their performance. Inspections should include checking for cuts, punctures, cracks, and other visible signs of damage. If any damage is detected, the tire should be replaced immediately to avoid the risk of tire failure.

Solid Tyres should be mounted by a professional to ensure that they are properly aligned and balanced. Improper mounting can lead to premature wear, uneven tread wear, and other issues that could affect the tire's performance and safety.

Solid Tyres should be stored in a cool, dry place away from direct sunlight and sources of heat. Exposure to extreme temperatures or sunlight can cause the tire to deteriorate and lose its strength and durability.

Solid Tyres should be cleaned regularly to remove debris and other contaminants that could cause damage or reduce performance.

Solid Tyres should be used only on appropriate surfaces and within the recommended speed limits. Driving on rough terrain or at excessive speeds can cause the tire to wear prematurely, leading to a potential safety hazard.

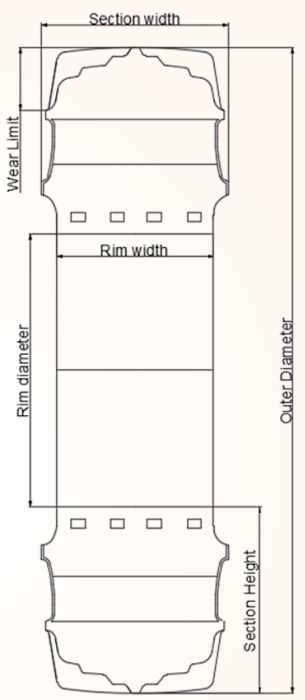

7.00 Section width in inch

12 Rim diameter in inch

18 Outer diameter in inch

7 Section width in inch

8 Rim diameter in inch

225 Section width in mm

75 Aspect ratio (Section Height / Section Width)

15 Rim diameter in inch

Upto this line tyre can be used.

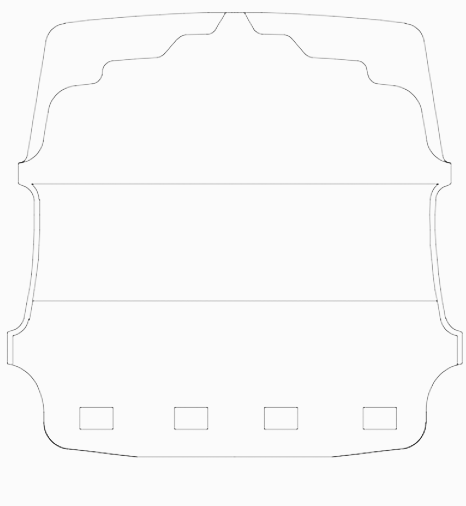

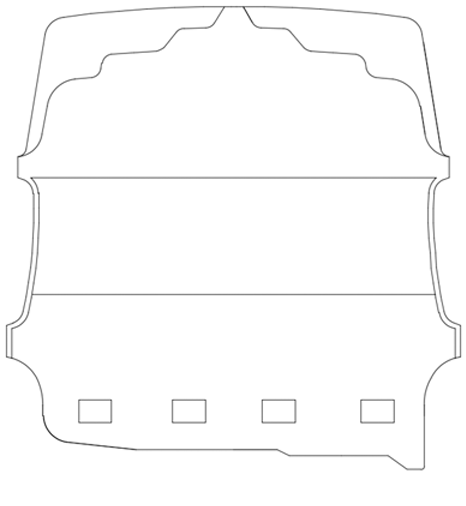

Goliath

To protect rim from damage.

Rubber King

6.50-10.

Safety Line

Upto this line tyre can be used.

Product Name

Goliath

Rim Guard

To protect rim from damage.

Brand Name

Rubber King

Tyre Size

6.50-10.

Like pneumatic tyres, solid tyres also designed for a particular load carrying capacity.

Solid tyre fitment must be done using "Fitment Press"

Solid Tyres should not be used beyond "Safety Line"

Always "Lift" Forklifts fitted with solid tyres while shifting to distance location instead of driving through road.

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatumdeleniti atque corrupti quos dolores et quas.

| 3.00 | — | Rim/wheel width in inch. |

| D | — | Rim/wheel profile. |

| 8 | — | Nominal rim/wheel diameter in inch. |