Rubber King Tyre Private Limited, a flagship company of Gawarvala Group, a respected business family from the state of Gujarat, India. Rubber King Specializes in manufacturing its product range, with 4 state-of-art manufacturing plants located in the state of Gujarat.

Leading Manufacturers and Exporters of Solid Cushion Tyres, Pneumatic Tyres, Automotive Butyl Inner Tubes, Flaps and Tyre Curing Bladders

Discover Our Range of Products

We Specialize In

We Specialize In

Solid Tyre

Rubber King Resilient solid tyres meet the wide ranging requirements of material handling industry. This is achieved by use of high quality raw materials, unmatched compounding techniques and superior building technology. The Plant is equipped with best in class equipment imported from world leaders in respective fields.

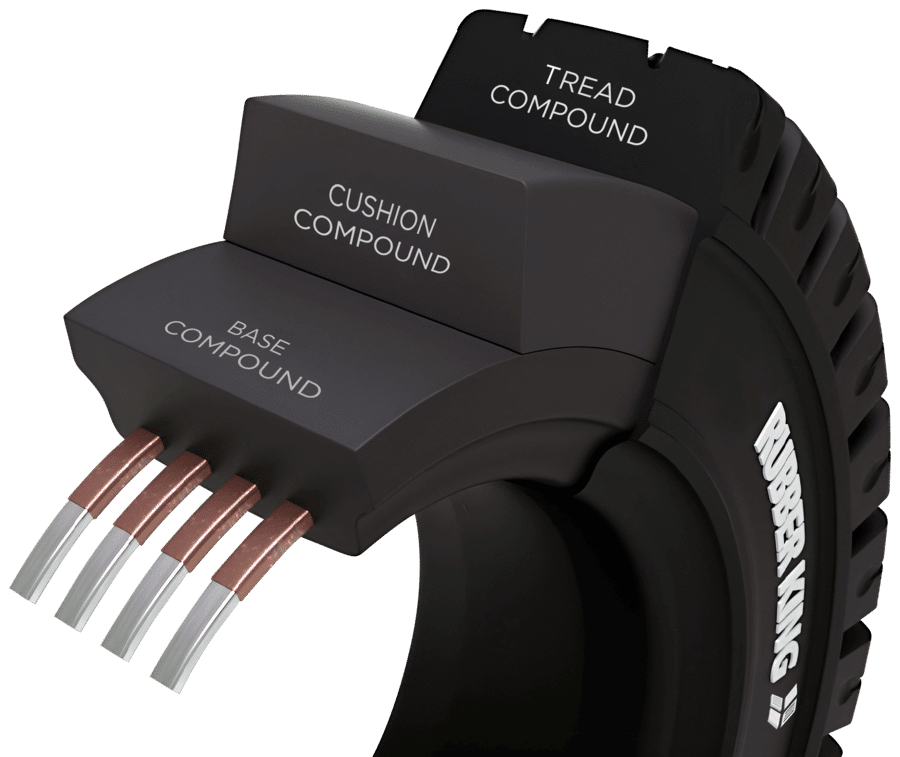

Design

Pneumatic Tyres

Rubber King Pneumatic Tyres are with unique lettering on sidewall that visible at first glance. They have strong nylon casing that increase resistance to punctures and improve overall strength. They made with special tread compound with enhance tread mass distribution that optimize treadwear and performance.

Tube

We manufacture excellent quality inner tubes for automotive tyres using high quality raw material following accepted international manufacturing standards. We are OE suppliers to major tyre manufacturers.

Chloro-butyl

Chloro-blend

Products

Flaps

RUBBER KING tyre flaps are designed to protect inner tube from direct contact with metal rim even at severe service condition. It guarantees longer work life to inner tubes and tyres.

compound.

protectors.

Bladders

RUBBER KING tyre curing bladders are a preferred choice for major Tyre manufacturers for their green tyre curing process. We have a vast range of curing bladders suitable for a range of tyre sizes, both radial and bias construction.

Bias & Radial Tyres

"Heats"

Find Your Tyre

Find Your Tyre

*Customer needs to verify the RIM size.

Engineering Design

Rubber King Resilient solid tyres are design for aggressive applications, suitable for both indoor and outdoor usages for long runs on surfaces varying from smooth concrete to abrasive floors to rough surfaces.

Excellent resistance to abrasion with superior cut, chip and wear resistance compound assures longer tyre life with lower rolling resistance.

Excellent resilient compound offers cushioning effect thus assuring comfortable ride.

Though and low resilient compound ensures perfect bounding with cushion and bead compound assuring higher stability. Copper coated steal bead wires are used for better anchoring on RIM.

Rubber King Resilient solid tyres are design for aggressive applications, suitable for both indoor and outdoor usages for long runs on surfaces varying from smooth concrete to abrasive floors to rough surfaces.

Excellent resistance to abrasion with superior cut, chip and wear resistance compound assures longer tyre life with lower rolling resistance.

Excellent resilient compound offers cushioning effect thus assuring comfortable ride.

Though and low resilient compound ensures perfect bounding with cushion and bead compound assuring higher stability. Copper coated steal bead wires are used for better anchoring on RIM.

Manufacturing Excellence

Manufacturing Plants are designed and upgraded to meet any of International Standards of Quality Management System, Energy Efficient, Environment Friendly and Safe Manufacturing System .

Sophisticated Technologyat Rubber King

Maximize your Saving

Rubber King tyres having lesser CPH (Cost per hour),which means more profit your business.

Ensures Forklift Uptime

No surprise breakdowns can plan tyre change based on "safety line" marking.

Reduces Environmental Impact

REACH compliance compound.

Certificates

Capexil Award

- 2010-2011

- 2009-2010

- 2008-2009

- 2006-2007

- 2004-2005

- 2002-2003

Testimonial

News & Events

News & Events

Agritechnica, Germany

Exhibition Grounds, Hannover, Germany Hall : 04, Booth : E-43 Date : 9th – 15th November, 2025 Agritechnica, one of the world’s leading trade fair for agricultural machinery and technology, proved to be a noteworthy experience as we engaged with the global leaders, innovators, and professionals from the agriculture and farm equipment sectors. Visitors from […]